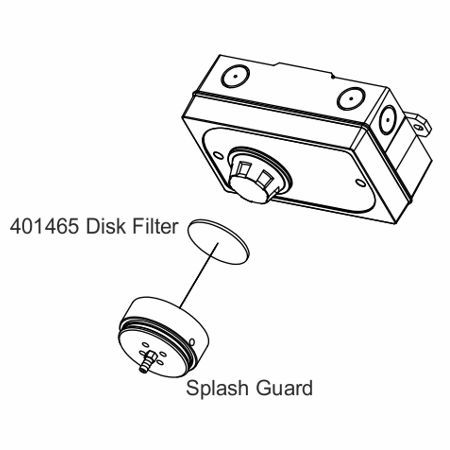

Splash Guard Gas Detector

One of the main dangers for detectors placed at low level, is contamination from liquid splashes, dirt and impact damages. These hazards will damage the detector over time causing a shorter than average life expectancy for the fitted detector. Gas detector Splash Guards protect the detector.

. Industry-leading speed & response: T90 ≤ 3 seconds even with splash guard installed. No routine calibration required reducing maintenance costs. Industry standard 4-20 mA output provides remote alarm and fault indication. Multiple communication outputs provide complete status and control capability in the control room. Heated optics eliminate condensation. Dirty optics indication discriminates between true fault and cleaning requirements.

Fast calibration times reduce amount of cal gas required which lowers maintenance time and costs.

Types of Safety ShieldsRAMCO Safety Shields are manufactured in various materials that resist the hazardous or toxic chemicals commonly used in process industries at varying temperatures and pressures. By selecting the appropriate material for an application, virtually all situations can be safeguarded.Safety shields for flanges are most frequently specified, followed by valve safety shields. From the standpoint of safety, all pipe joints are critical, since a sprayout can occur at any connection. However, the likelihood of a sprayout is greatest from flanges because their use outnumbers all other connections. Should a leak become uncontrolled, the consequences can be devastating.RAMCO Safety Shields are manufactured for all pipe connections such as: FlangesValvesCouplingsValvesof All KindsUnionsExpansionJointsElbowsFlowMetersTeesHose CouplingsClampsHeat ExchangersPumpsPressure VesselsInstrumentsCustomized ConnectionsTube FittingsRAMCO Safety Shield Options:Each group, in turn, contains shields that are manufactured from different materials — a total of eight are currently available.

Each type can be fabricated in any size to accommodate the pipe system. While this selection is sufficient to handle virtually all applications, special safety shields can be customized on request.One major difference among the wide variety of RAMCO® Safety Shields is. Up to 140°F (60°C) Econo-Gard® Shields are recommended, whereas TFE Spra-Gard® Shields resist temperatures up to 450°F (232°C).

Beyond this, Metal Shields are required, demonstrating heat resistance as high as 2650°F (1454°C). Although there are situations in which higher temperatures occur, RAMCO® Safety Shields are not suitable for these environments.RAMCO® Safety Shields are available in all piping standards (ANSI, DIN, BS, JIS, etc.) and can be customized for special sizes and configurations.Other Safety Shield Information. RAMCO Spra-Gard® Safety ShieldsFlange Spray Guards, Valve Spray Guards, Spray Shields, Valve Shields, Flange Covers, Valve Covers, Leak GuardsRAMCO® Spra-Gard® Safety Shields, the work horse of safety shields, are most frequently specified because of their wide range of physical characteristics.RAMCO® Spra-Gard® Safety Shields are fabricated in three proprietary thermoplastic textiles:. Tetrafluoroethylene or TFE-Coated Fiberglass. Polypropylene (PPL or Polypro).

ECTFEThe two woven cloths — TFE and PPL —are developed exclusively for RAMCO® according to specifications. These fabrics are produced to a patented design and a 'porosity concept’’ that has been very carefully engineered. Rather than using impenetrable fabrics, Spra-Gard® Safety Shields are made of slightly porous textiles — too slight to permit a sprayout but sufficient to allow fluid to seep through to the indicating patch in the event of a leak.ECTFE, a fluoropolymer clear film, is the material that forms the wide center band of the Spra-Gard® 'See-Thru' Shields. This non-flammable film withstands temperatures up to 300°F (150°C) and has very high tensile strength. It also demonstrates excellent chemical resistance.Another common feature of Spra-Gard® Shields is the sensitive pH patch or indicator that is incorporated in each safety shield. Should the slightest amount of leaking fluid come in contact with the patch, the patch undergoes color change immediately signaling trouble in the line.

Auto Splash Guards

Yellow/orange in color, the indicator turns brilliant red with an acid leak and bright green with an alkali leak. While the affected patch can no longer be used, it can be removed and replaced with another patch after the shield has been neutralized.

The shield is then ready for reuse.Spra-Gard® Safety Shields have an overlap design. The shields wrap around the pipe connections completely to prevent a lateral sprayout. During installation, they are held in place by means of a velcro fastener. No tools are required, and a single installer can secure a shield over a flange or valve in less than a minute.Each shield has a pair of tie-down cords. After it has been positioned over the joint and held firmly by its velcro fastener, the cords are drawn tightly around the pipe and secured with a square knot.

Use of a square knot is essential, since pressure exerted against a square knot will tighten, ensuring that the shield will maintain its position over the pipe connection.All Spra-Gard® Shields have been subjected to ultraviolet (UV) testing and have performed without degradation for approximately 500 hours.Material is considered acceptable if it withstands approximately 200 hours of exposure without degradation. This is equivalent to approximately four to five years of outdoor exposure in the tropics and even longer in a temperate zone. Thus, Spra-Gard® Shields are inhibited against ultra-violet rays and can be installed both indoors and outdoors.Other critical features of RAMCO® Spra-Gard® Safety Shields are their ability to resist ignition and flame propagation.Because each Spra-Gard® Safety Shield is produced from a different thermoplastic cloth, parameters for pressure and and chemical resistance vary.

RAMCO Valve-Gard® Safety ShieldsFlange Spray Guards, Valve Spray Guards, Spray Shields, Valve Shields, Flange Covers, Valve Covers, Leak GuardsBecause of the wide range of harsh environments and performance requirements in the chemical processing industries, a wide selection of valves is necessary. However, approximately one-third of all chemical plant emissions come from equipment leaks — and valves are the biggest potential source of leaks and sprayouts. They are a major weak point in a piping system because they contain several areas from which leaks or sprayouts can occur.When selecting a valve, in addition to process fluid, of the line, the operating principles of the major valve groups also should be considered.

And lastly, another important factor is the appropriate selection of a safety shield.Safety shields for valves complement those for flanges, providing a system that protects employees from injuries and equipment from damage and shut-down.Unlike flanges, valve dimensions vary extensively, both among manufacturers and styles. Due to this wide variance in specifications, each valve shield requires its own design. To address this challenge, RAMCO® maintains an extensive library of US and International valve manufacturers. And with changes in valve technology, these data are updated.Valve-Gard® Safety Shields: Valves with StemsButterfly, ball, plug and diaphragm valves present a common design consideration in the fabrication of Valve-Gard® Shields. The shields fabricated for these valves envelop the entire body of the valve and any mating flanges. A small opening is made for the stem to protrude for either manual or automatic operation.Valve-Gard® Shields are designed for installation over existing in-line valves and require no mechanical adjustment or separation of the valve from the pipeline.Special valves with multiple ports, multi-valve configurations or valves with instrumentation can also be fitted with appropriate Valve-Gard® Shields.Control and actuated valves are also candidates for Valve-Gard® Shields.

As long as the manufacturer’s name and valve model number are provided, a safety shield can be fabricated easily.Valve-Gard® Safety Shields: Valves Without StemsValve-Gard® Shields are also available for most types of check valves. They are constructed in a similar fashion to ball and plug valves but do not require an opening for a stem. Check valve shields cover the valve and mating flanges as a single unit. RAMCO Econo-Gard® Safety ShieldsFlange Spray Guards, Valve Spray Guards, Spray Shields, Valve Shields, Flange Covers, Valve Covers, Leak GuardsBecause of the apparent need for an economical but dependable safety shield, RAMCO® developed the Econo-Gard® Safety Shield. Great attention has been paid to its design to ensure that its economic features have not been achieved at the expense of safety.

The modest price of this shield is possible because its fabrication utilizes non-labor intensive heat sealing methods.Econo-Gard® Safety Shields are available in two thermoplastic materials:. polyethylene (PE). polyvinyl chloride (PVC) (white, red and clear)While each of the Econo-Gard® Safety Shields has slightly different characteristics, depending on the materials from which they are fabricated, both are manufactured with the same design and feature identical configurations.The conditions under which Econo-Gard® Safety Shields may be used are limited. They are suitable for temperatures up to 140°F (60°C) and in the presence of certain chemicals, such as concentrated acids, only at lower temperatures. However, they have wide applications, particularly in conditions with ambient temperatures and pressures of 300 psi (21 bar) or lower.Similar to Spra-Gard® Shields, Econo-Gard® Safety Shields also wrap-around. Produced from special thermoplastic materials according to RAMCO® specifications, these shields are a three-ply lamination with an inner core of non-woven spun cloth interfaced between two sheets of either PE or PVC. Consequently, a sprayout is prevented by six layers.

Four layers, consisting of PE or PVC film, are chemically resistant; the remaining two of non-woven spun cloth provide tensile and burst strength.Indicating pH patches to signal leaks are also incorporated in Econo-Gard® Safety Shields. Several weep holes behind the patch allow a slight flow of chemical to the indicator which then undergoes color change, alerting plant personnel to the presence of a leak.The clear PVC Econo-Gard® Safety Shields have the same high quality characteristics of the Econo-Gard® Safety Shields with the added benefit of a 'See-Thru' feature, permitting easy visual inspection of pipe joint – flanges, valves and threaded connections.

Sewer Gas Detector

Because of the 'See-Thru' feature of this shield, an indicating pH patch is not needed.Subjected to UV testing, Econo-Gard® Safety Shields withstood approximately 430 hours of testing, and at that time demonstrated slight blistering.This period is equivalent to approximately eight to nine years of outdoor exposure in a temperate climate. Consequently, both PE and PVC Econo-Gard® Safety Shields may be installed either indoors or outdoors.Econo-Gard® Safety Shields are appropriate for installation in chemical processing industries in which less hazardous chemicals at low temperatures and pressures are utilized. Food processing and waste water treatment facilities are typical applications for these shields.

Phosphate mining is a specific application for PE Shields, and seawater desalination plants are high users of PVC Shields. RAMCO® Metal Safety ShieldsFlange Spray Guards, Valve Spray Guards, Spray Shields, Valve Shields, Flange Covers, Valve Covers, Leak GuardsRAMCO® uses 24 gauge steel exclusively for its metal safety shields. This gauge, approximately 25 thousandth of an inch thick, is ideal for safety shields. It is sufficiently heavy to withstand high pressures and also has flexibility to permit shaping.RAMCO® has developed specialized equipment for production of its shields, and use of its manufacturing methods results in high volume production at relatively low cost.Three metals are used for RAMCO® Safety Shields:. Galvanized steel.

'304' stainless steel. '316' stainless steelGalvanized steel is installed widely for water, oil and steam applications. The galvanized material is steel that has been coated with zinc to reduce rusting. It is vulnerable to corrosive attack and should not be used on lines carrying hazardous chemicals.

When installed on vessels, it is mandatory that the shield be equipped with a special inner galvanized mesh lining that breaks up the impact of a jet spray on the shield surface, eliminating up to 90% of lateral aerosol mist. RAMCO® uses stainless steel '304' and '316' alloys specially developed for corrosive applications.

Stainless steel '304' contains 18-20% chromium and 8-10.5% nickel and is suitable for applications requiring mild corrosion resistance. In contrast, stainless steel '316' contains 16-18% chromium and10-14% nickel as well as 2-3% molybdenum. The latter component gives superior resistance to pitting and to most types of corrosion, making '316' suitable for applications involving severe corrosive conditions. These safety shields are also available with inner stainless mesh linings.Since the heat limit for a thermoplastic shield is approximately 450°F (232°C), the use of stainless steel safety shields is required whenever conditions in the line exceed this temperature.

Natural Gas Detector

The choice between '304' and '316' depends on which is likely to suffer the least corrosive attack. Stainless steel with a thickness of 24 gauge has a tensile strength of 3000 psi (207 bar), and a melting point of approximately 2650°F (1454°C). Although some pitting may occur due to corrosive fumes, stainless steel safety shields can be expected to provide many years of effective service. They have been approved by the United States Department of Agriculture for installation in food processing plants.In isolated circumstances, it has been observed that chemicals may be present in the external environment that are incompatible with RAMCO® thermoplastic safety shields. This unfavorable, aggressive climate causes shield damage. With these conditions, installation of stainless steel safety shields is recommended, even though the line temperature may be less than 450°F (232°C).RAMCO® Metal Safety Shields are suitable for flanges and every type of valve in all size systems carrying steam, solvents, chemicals and corrosive agents.

They are appropriate for all high pressure and temperature applications. The shields slip over existing pipe installations and are put in place easily and quickly with the use of a screwdriver.In the event of a leak, the fluid collects at the bottom of the shield where the overlapping slotted edge prevents a lateral blowout and allows the leaking condition to be highly visible without causing injury to plant personnel and equipment. RAMCO® Specialized Safety ShieldsFlange Spray Guards, Valve Spray Guards, Spray Shields, Valve Shields, Flange Covers, Valve Covers, Leak GuardsIn addition to a full product-line of Spra-Gard®, Econo-Gard® and Metal Safety Shields, RAMCO® produces shields that provide protection under special plant conditions:. Expando-Gard® Safety ShieldsThe most frequently ordered Expando-Gard® Shield is fabricated of TFE, followed by the 'See-Thru' Vue-Gard®, the PPL (Vue)-Gard®, and then, PPL. These are the only materials in which Expando-Gard® Shields are manufactured.Expansion joints are important integral parts of piping systems but they have a tendency to leak and to create sprayouts with disquieting frequency. These joints may have convolutions of rubber, plastic or stainless steel, and Expando-Gard® Shields are suitable for all three types, regardless of manufacturer.Effective shielding of an expansion joint must envelop the piping connection and must, at the same time, have the ability to retain its position firmly, even when exposed to intense pressure, as in the case of a surging leak.A flange has a fixed configuration and accordingly, to design a shield with a tight fit is relatively simple. In contrast, an expansion joint expands, contracts and misaligns.

The RAMCO® Expando-Gard® Shield provides for these dimensional changes without inhibiting the motion of this device. This innovative shield wraps around and fits snuggly over the joint, providing the needed protection in the event of a hazardous chemical leak.An early leak can be detected by the indicating patch on the Expando-Gard® Shield (except for the 'see-thru' Shields).

This patch changes color immediately on exposure to an acid or base. As with all RAMCO® Shields, the materials that are used in the manufacture of the Expando-Gard® Shields are non-flammable and non-combustible, including the tie-cords.Expando-Gard® Shields may be produced for any pipe size or may be customized to any non-standard specification. To fabricate Expando-Gard® Shields of any RAMCO® material, the following information is required:. Face-to-Face of the expansion joint (nominal length). Pipe size. Number of convolutions.

Number of limit bolts (control rods)These unique, specialized shields are installed with ease, and just as with flange safety shields, no tools are required.This RAMCO® Safety Shield has been recognized as contributing significantly to the advancement of safety in chemical processing. It was given the National John C. Vaaler Award as 'a major contribution toward more efficient and effective operation of plants in the chemical processing industries'. RAMCO® Safety Shields for Threaded FittingsFlange Spray Guards, Valve Spray Guards, Spray Shields, Valve Shields, Flange Covers, Valve Covers, Leak GuardsRAMCO® has developed safety shields for threaded fittings, such as elbows, couplings, unions and tees.

They are available in Econo-Gards® — PVC and PE — and Spra-Gards® — TFE, Vue-Gard®, PPL (Vue)-Gard® and PPL materials.Metal Safety Shields are available for unions and couplings only.Similar to Spra-Gard® Shields and Econo-Gard® Safety Shields, shields for threaded fittings contain pH indicating patches, velcro fasteners and tie cords. Since the 'See-Thru' Shields permit direct visualization of the threaded connection, an indicating patch is not needed.These shields, regardless of configuration, are installed easily without tools.